vickers hardness test conclusion|astm e92 pdf free download : importer Despite its limitations, the Vickers hardness test is one of the more reliable hardness testing procedures to date. Its wide scope of application and the ease of maintenance for its testers make the test a viable addition to . WEBA “Garota Ciborgue”, também conhecida como “Menina Cyborg” ou “Portal Zacarias Menina Cyborg”, é uma figura enigmática que surgiu na plataforma do WhatsApp. Ela é o resultado de um avanço notável em tecnologia digital e programação, e é reconhecida por seu físico complexo que é surpreendentemente realista, apesar de ser .

{plog:ftitle_list}

Based on the Xiangling copypasta from Genshin Impact. I ca.

Conclusion: The purpose of this experiment was to determine which of the five materials tested was most suitable for the production of 500 HV30 automobile .

Plastic Film Tester inc

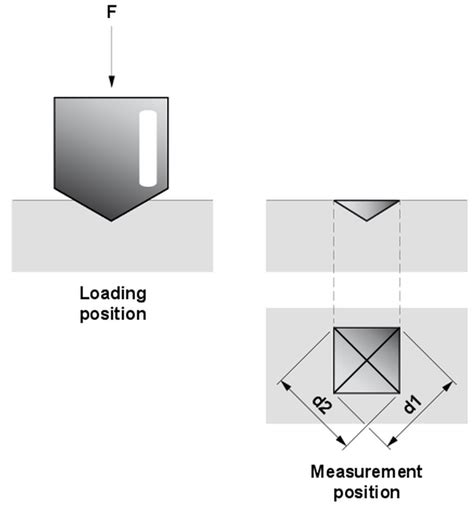

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which . Despite its limitations, the Vickers hardness test is one of the more reliable hardness testing procedures to date. Its wide scope of application and the ease of maintenance for its testers make the test a viable addition to . The Vickers hardness test measures the maximum load applied to an object without its deformation exceeding a specified value. To measure the hardness, a diamond .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low . In conclusion, the Vickers hardness testing method is a powerful technique for assessing the hardness of various materials. Its principles are grounded in precise indentation measurements, allowing for accurate material .A method that can be used for figuring out a material’s hardness—a measurement of its resistance to deformation in the presence of force—is the Vickers hardness test. While it .

Mechanical Engineering. Vickers Hardness Test: What it is and how it’s measured. • The Vickers Hardness test can help with the material selection process for your chosen application. • The .

The Vickers test is easier than other hardness tests since the required calculations are independent of the size of the indenter and the indenter can be used for all materials irrespective of hardness. Principle. The indenter is made .

Here are a few of the most important factors to consider to ensure an accurate conclusion from a hardness test. External factors such as light, dirt, vibrations, temperature, and humidity should be controlled . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test .

Vickers Hardness Test; In Vickers test, it involves a diamond indenter in the form of a square-based pyramid with an apex angle of 136 ̊. The indenter is being pressed under load for 10 to 15 seconds into the surface of the specimen .In conclusion, the Vickers hardness test is a versatile and trustworthy method for assessing material hardness. Understanding its principles and acquiring the appropriate equipment and instruments will enable precise testing and .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the same indenter (a pyramidal diamond) can be used for all materials, irrespective of hardness. .

The Vickers hardness test utilizes a diamond pyramid shaped indenter that is ground in the form of a squared pyramid with an angle of 136o between faces, and the depth of indentation is about 1/7 of the resulting impressions diagonal length. . CONCLUSION In this experiment, the hardness of the specimen is determined by using a Vickers . Conclusion: The Vickers Hardness Test is a powerful tool in the field of metallurgy, offering accuracy, versatility, and reliability in assessing a material’s hardness and mechanical properties. Its ability to cover a broad range of materials and hardness levels, along with its applicability to microhardness testing, makes it a preferred .

The Vickers hardness test can be a micro indentation test and also for the macro hardness test. It is mainly divided into two steps. The test force (load) F is applied on the specified square base pyramid shaped diamond indenter for the specific time when it collides with the testing sample object in the direction normal to the test surface.Conclusion. The Vickers Hardness Test is an extremely accurate, fast, and easy test method. It can be used to test a wide range of materials such as thin aluminum foils and other micro-structural materials. It has a high surface finish for fine-grain metals and can be performed on bulk, sheet or wire materials. . View Lab - report 1 (Vickers Hardness Test).docx from BMM 1511 at University of Malaysia, Pahang. BMM1511 Engineering Mechanics Lab 1 Lab E1 Vickers Hardness Test Section/Group Section 02 Group. . 5.0 CONCLUSION In this experiment, when the Vickers hardness of specimen position for welded . Vickers hardness testing also is known as the Diamond pyramid hardness test. Because we use the Diamond pyramid as the indenter. . Conclusion. We have discussed how the test is conducted and the principle of the Vicker’s hardness test. and also we have discussed the precautions that we have to take before we begin the test.

Conclusions (CO4:PO9) 5; Overall impression of report (CO4:PO9) 5. Team works (CO4:PO9) 5 TOTAL 51; . The Vickers hardness test method also referred to as micro hardness test method is mostly used for small parts, thin sections or case depth work. The Vickers method is based on an optical measurement system. The micro hardness test procedure .

Hardness evaluation is a critical aspect of material testing, providing insights into a material's resistance to deformation and wear. Among the various methods employed for hardness testing, the Vickers test stands out for its precision and versatility.. The Vickers test, developed by George E. Sandland and Robert L. Smith in 1921, utilizes a pyramidal diamond .

vickers hardness test procedure pdf

The Vickers hardness test method, otherwise called a microhardness test method, is used for small objects, thin sections, as well as the case depth work. . Conclusion. To wrap this up, given the drawbacks of the Vickers hardness tester as regards the coating thickness, which is likely to affect measurements, nanotechnology advancements have .Objective: The Vickers hardness test mainly serves to measure the hardness of materials, its physical durability. Hardness is defined as a material's “resistance to deformation” (#1) and it can vary depending on the material. . Conclusion: The purpose of this experiment was to determine which of the five materials tested was most suitable .Vickers number 1 2 Average 1 0 0 0 312. 2 0 0 0 315. 3 0 0 0 317. 4 0 0 0 292. ANALYSIS Hardness Value: A measurement of the material's hardness is provided by the test's Vickers hardness number. Greater hardness is .

Conclusion. The Vickers hardness test is a common, widely used method for measuring the hardness of materials. It is an excellent method when testing softer materials that could not withstand the forces required by other standards such as Brinell, Rockwell, or Mohs scale. Therefore, using the Vickers scale in mechanical testing is recommended .Vickers hardness test is a micro testing method used for some specified cases. Sometimes it becomes necessary to change the hardness value from one scale to another. . Conclusion. Rockwell Hardness test is the most widely used method but in some cases Vickers Hardness testing method has to be used especially when thin parts have to be tested . The Vickers Hardness Test involves pressing a pyramid-shaped indenter with a precisely known load into the material's surface. The indenter typically has an angle of 136 degrees between opposite faces. . Conclusion: Measuring microhardness with the Vickers Hardness Scale provides a reliable and accurate means of assessing the hardness of . The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface.

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals.

The Vickers hardness test is more accurate than the Rockwell hardness test because of the use of a microscope to measure the indentation. Cost: . Conclusion. The hardness test methods are fundamentally different in how they determine a material’s hardness value. The Rockwell hardness test uses a simple mechanical load application, while the .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

The Vickers hardness test measures the ability of a surface to resist penetration when pressed by a fixed force. In other words, it measures how much pressure is needed to embed an indenter into a material and measure its impact on a load cell. . Conclusion. The Vickers hardness test can measure the relative hardness of different metals and .VICKERS HARDNESS TEST: The Vickers hardness test uses a square base diamond pyramid as the indenter. The included angle between the opposite faces of the pyramid is l36°. The Vickers hardness tester operates on the same basic principle as the Brinell tester, the numbers being expressed in the terms of load and area of the impression.

Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting. Hardness testing is an essential test in the metal manufacturing industry, and Vickers hardness is one of the most widely used hardness measurements today. The computer-assisted Vickers hardness test requires manually generating indentations for measurement, but the process is tedious and the measured results may depend on the operator’s experience. In .

The Vickers Hardness Testing is a cornerstone technique for evaluating the hardness of assorted materials, mainly metals and their types. Formulated in 1921 as a simpler recourse to the Brinell test, it estimates a material’s resistance to deformation under a consistent burden. . Conclusion. The Vickers Hardness Test remains a useful .

vickers hardness test manual

Dorm Room Sisters Mangá Hentai Online grátis - HentaiTec.

vickers hardness test conclusion|astm e92 pdf free download